Scara Elite Roadrunner

Scara Elite Roadrunner

Scara Elite v2 Printer combined with our Roadrunner track. It adds another axis of control, allowing you to make even larger creations, such as full size structures and walls. Include a pump and you are ready to start printing.

The Scara Elite is deigned to work with a pumping system, such as our Small 50 Pump: https://3dpotter.com/cement-printers/mighty-small-50

Please contact us to purchase this item. We only accept cash, check, or wire transfer for this item. All credit card purchases incur a 3% fee.

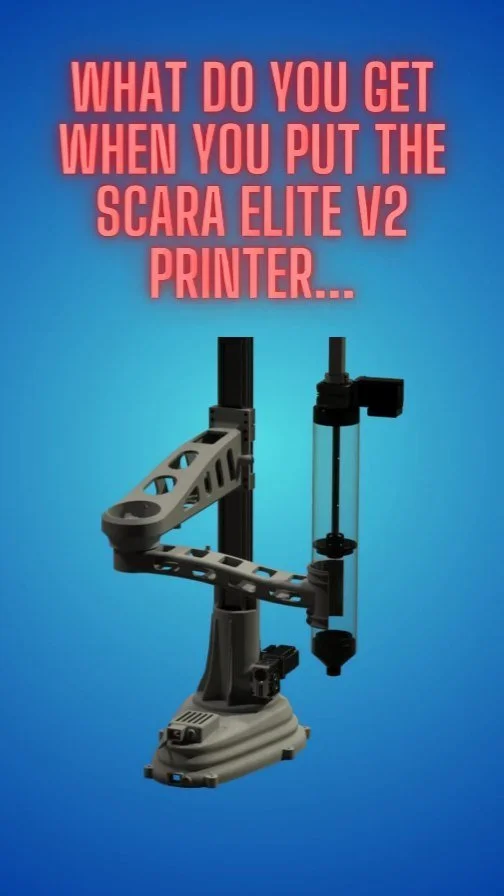

Potterbot Scara Elite v2

User Interface (WiFi)

Duet Web Control is a fully developed UI for the Scara. Opened in a web browser, it can be used on your laptop, tablet, phone, or other WiFi capable device.

The Scara Elite combined with our Roardrunner rail system provides an industrial size print area. You can print full structures and walls using our pump system. There is no limit to your creations with this machine.

What's included:

1. Scara Elite v2 and Roadrunner Rail System

2. Power Supply

4. Hex key set

Specifications

Printing Envelope:

X- 248” (6300mm)

Y- 110” (2800mm)

Z- 68” (1727mm)

Minimum Printing Envelope:

X- 157" (4000 mm)

Y- 39" (1000 mm)

Printer size:

W-22” L-162” H-95”

Maximum Operational space needed: W-116” L-278” H-100”

Weight with rail system: ~120lbs. (~54kg)

Average speed: 1.2’’ to 3.9’’/s (30 to 100 mm/s)

Power Supply: Output - 24V ~15 amps, Input - 110-220V, 50-60 Hertz

Power consumption: 24V ~10 amps, ~240 Watt

Main controller board running Duet3D with Atmel SAM4E8E: 120MHz ARM Cortex-M4

Full control through web interface, no apps or software installation. Non-WiFi versions are available, please contact us if you would like this type of connection (Ethernet connection).

Some components may be re-manufactured

** https://en.wikipedia.org/wiki/Harmonic_drive

Print Status

Once a print is started, it shows information about the model being printed. Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

G-Code Files

The G-Code Files page allows g-code files for printing to be uploaded, edited, or downloaded. A summary of the file is given such as size, layer height, and what the file was generated by.

Software requirements

None! The only requirements is a web browserbrowser interface.

For object generation, the Scara Elite is similar to the rest of the 3D Potter line ceramic printers. It's is just like any other 3D printer which requires an STL file to be sliced by a third-party program. We recommend Simplify3D or Cura, and then loading the file to the SD card in the printer, which can be done over WiFi.

Build envelope

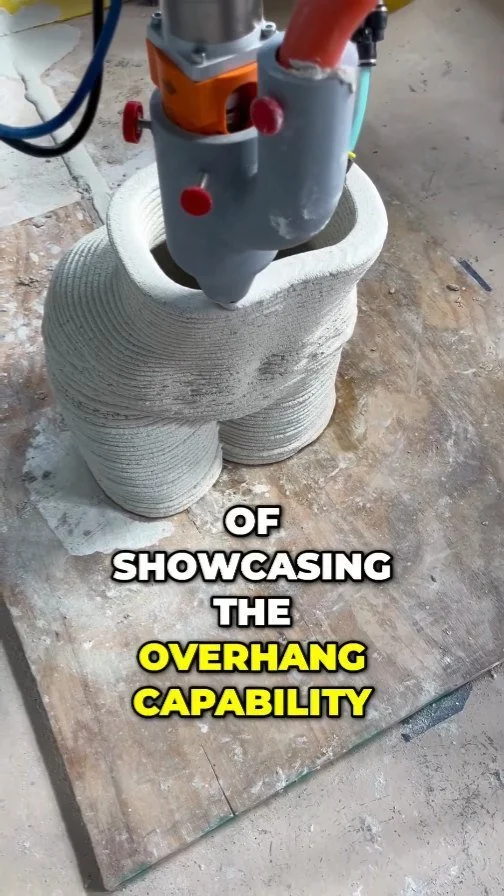

The build envelope diagrams represent the 45 in Z height. We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

The Scara elite build envelope is quite unique because it's capable of printing 360 degrees with continuous rotation. This means you can create a huge vessel with the printer initially residing inside the vessel or structure. This opens up a whole another opportunity to print small habitat structures (houses). Larger printers are available for this potential habitat project.

Another unique ability is printing multiple objects within the specified envelope in a sequential mode. For instance you could print a particular vessel starting on the far left side and continue to print these vessels until there is no more space left.

Speeds

The Scara Elite is capable of extreme speeds however speed is relative when it comes to ceramic 3D printing. Realistically you probably don't want to exceed 130 mm/s. There are many factors which determine the speed like nozzle size, layer height, and achieving a good adhesion on interlayer of the clay.

Construction and design

We were able to achieve high precision and accuracy with this large Scara arm robot only through diligent design and robust construction techniques. The majority of this structure is out of heavy aircraft grade 6061 aluminum utilizing CNC and welded components for maximum strength and rigidity. The main rail components are from IGUS* which is one of the leading German manufacturers of precision guide rails. The drive motors consist of very sophisticated hybrid closed-loop stepper motors. These have on-board computers with telemetry that continually update their position for zero error positioning.

Drive mechanisms

This is no souped-up 3D printer, this is a dedicated heavy duty purpose-built robot. The main drives are sophisticated harmonic drive units**. These are the same drives used on large industrial robots similar to the ones that are now in most of the large manufacturing facilities. These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

Space needed for setup

The real advantage is this machine can be positioned on a substantial table top and you can start printing right away within a limited envelope area. Or you can give it its own dedicated space for partial or full envelope.

The space needed is really determined by the end-user and how much of the print envelope they choose to use. Whether on the table top or on the floor, the Scara Elite will require direct mounting for maximum stability. This is achieved with multiple screws to secure the printer to the surface it is on. If you choose to use a tabletop it must be of substantial construction, the minimum is 1.5" thick heavy plywood or wood construction. If a inadequate table is used, the results from the printer will be diminished depending on the build envelope and speed at which the prints are created with.