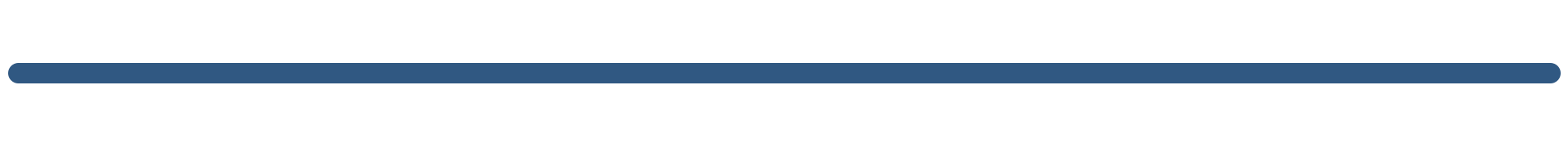

The Only Dedicated 3D Ceramic Printer Using REAL CLAY!

Our line of 3D Clay printers have some unique features when compared to other 3D printers. We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.

Our Most Popular Models:

3D Potter is world wide!

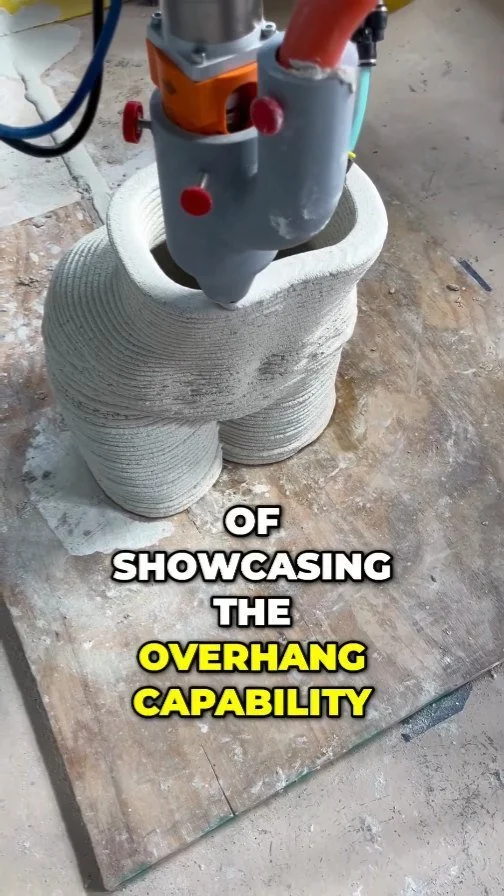

3D Potter has partnered with Sika to create a unique specially formulated 3D printing cementitious material

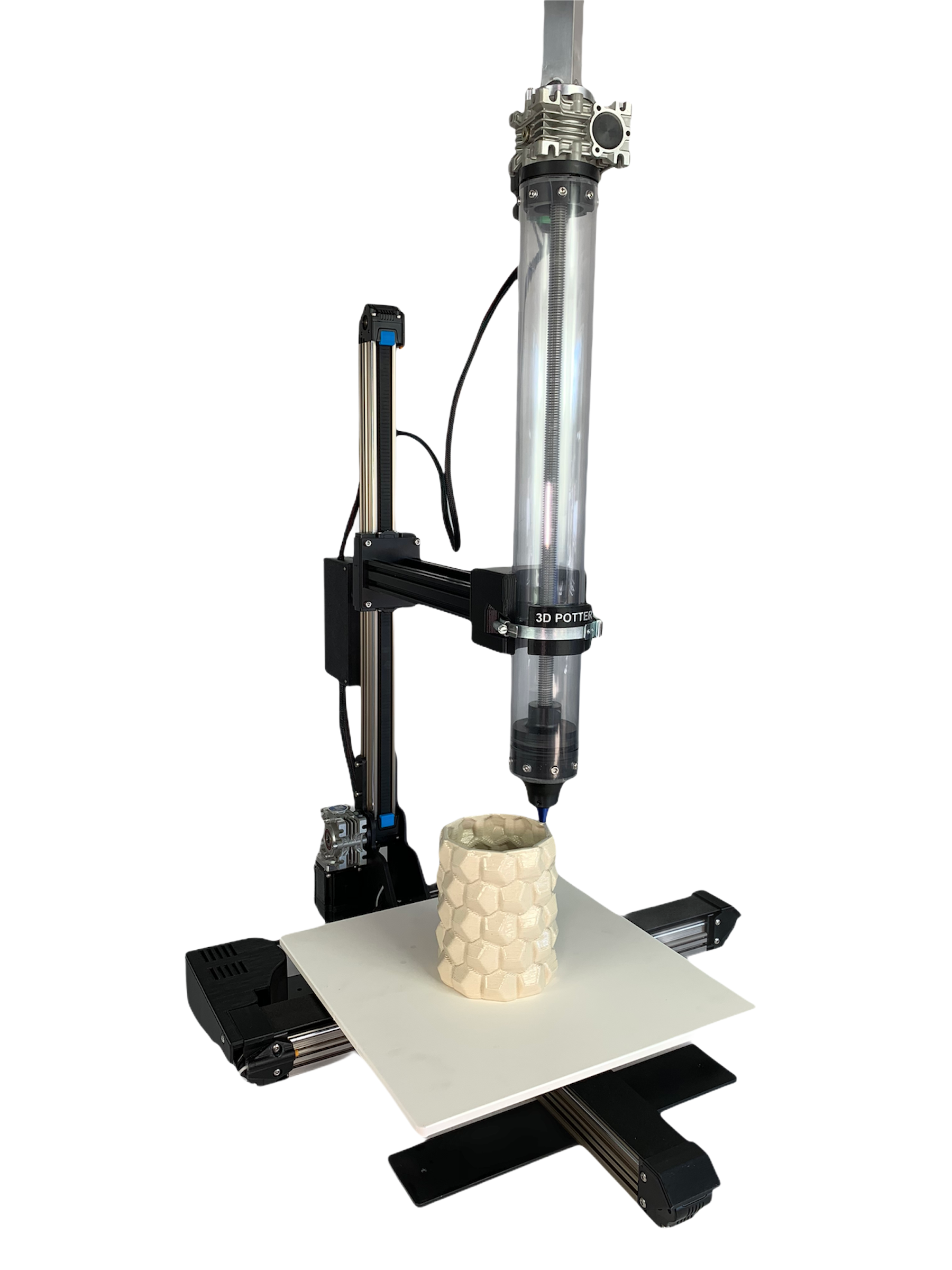

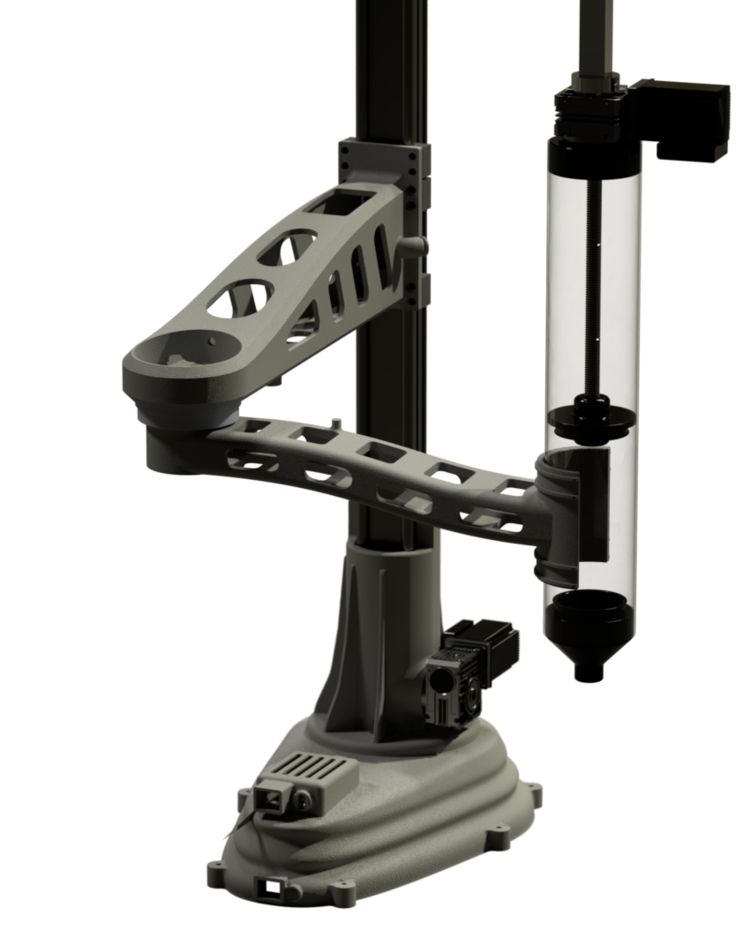

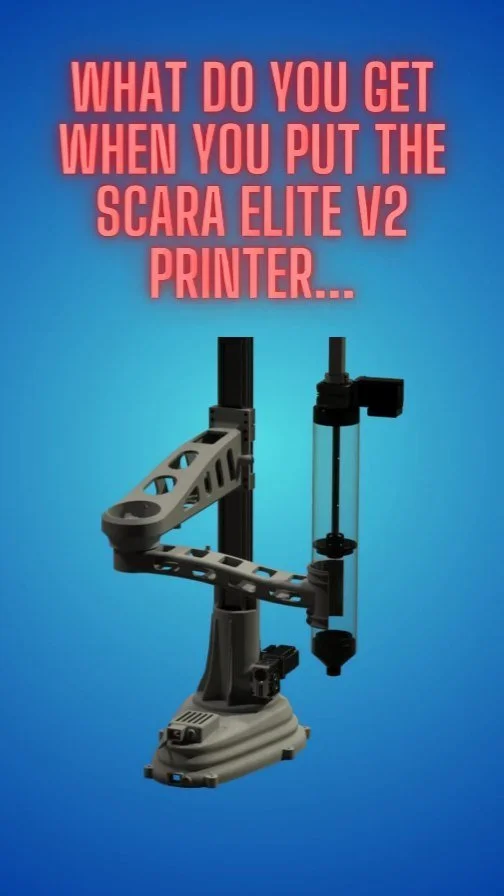

3D Printing Cement is here! We have combined our Scara Elite and Small 50 pump with Sikacrete® 3D printer cement developed by Sika USA. This is a versatile and convenient way of printing large-scale architecture and structures.

The Scara Elite is the first viable large-scale ceramic 3D printer using 3D printing material. It is capable of printing multiple objects non-stop. The Elite with the Small 50 can pump up to 3.5 gallons of material per minute through 85 feet of 1″ hose.

They work together so well, we decided to make them a package.

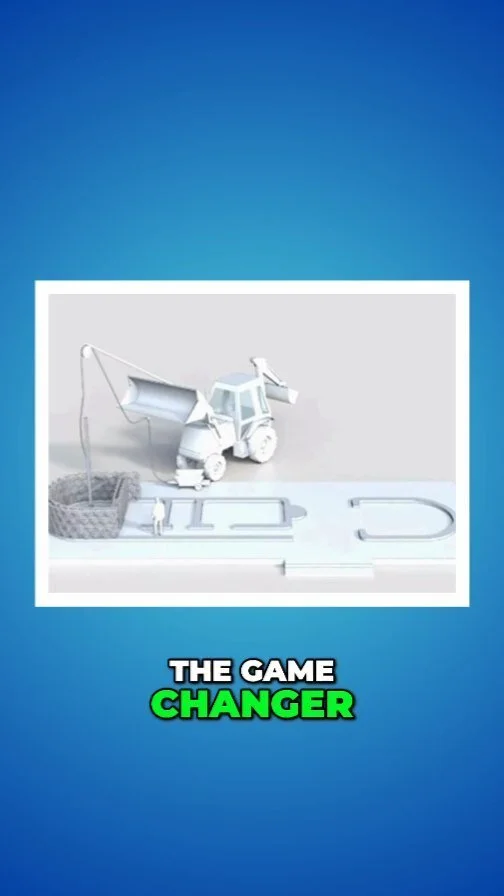

The possibilities are endless!