Why choose 3D Potter?

1. REAL CLAY

The most predominant point to be made about our system is that we extrude thick clay. Unlike other machines that run using air compressors and hoses and need diluted clay or slip, our extruders use thick clay. Basically, clay straight out of the bag with a small amount of water added.

2. LARGE PRINT

Our printers and extruders can print high-quality large-scale 3D prints, up to 36". This is due to the thick clay, and our use of large nozzles. We offer sizes from 1 mm all the way up to 16 mm.

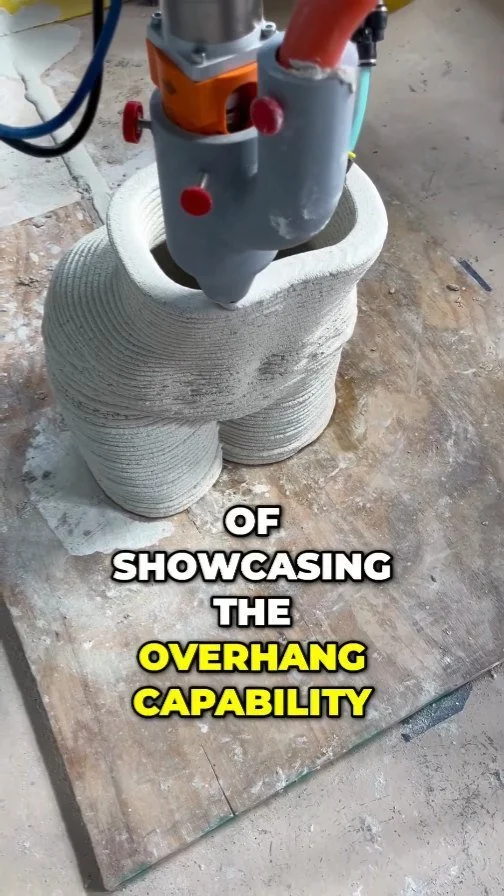

3. FAST PRINTING

Using thick clay and a larger nozzle you can print faster (130 mm/s) and taller (48") There is no need for drying or heating of the clay in order to get the support during printing. Even large vessels are capable of self-support. With larger nozzles, the layer height can also increase which shortens your print time.

4. CONSISTENCY

We prepare clay for printing in a de-airing pug mill. It is the main reason there are virtually no air bubbles in the printed vessels. Even if the tubes are loaded by hand with commercially available bag clay, there are very few air bubbles in the final print. That is key to achieving a superior consistency of the layer height.

5. REVERSING

Our extruders are capable of rapid reversing (retraction) which gives us the ability to stop and start during a print. This allows you to print more complicated shapes and vessels.

6. EASY MAINTENANCE

The clay can be left in our system for up to a month as long as the pressure is unloaded prior to storage. Virtually no other consumable parts are necessary to purchase other than clay.

7. NOZZLE SIZES

We offer nozzles from 1 mm all the way up to 16 mm. Our extruder prints directly from the nozzle of the extruder. This is a huge advantage. Through direct extrusion, we are able to use much thicker clay. With thick clay, you are able to print large objects at a faster rate and much larger in size.

8. LOW PRESSURE

Other machines use an air compressor to pressurize a hopper of clay which is then forced through a small hose to a nozzle. It is not possible to get thick clay through a hose assembly because of the pressures that build up from parasitic drag inside the hose. Additionally, the fluctuating air pressure in the compressor tank will cause your clay flow to change throughout the print.

The end result of this mechanism with hoses is that the clay is too thin in consistency to produce large self-supporting objects. This is why they use double-wall or intricate wall designs to be to support the print.

The setup, loading tubes, and cleaning of the 3D Potterbot is easy. When our extruder is empty, back off the screw, undo the nozzle, and wash it out, now you are ready for to reload. You can also load multiple tubes at one time saving you prep time and giving you more print time.

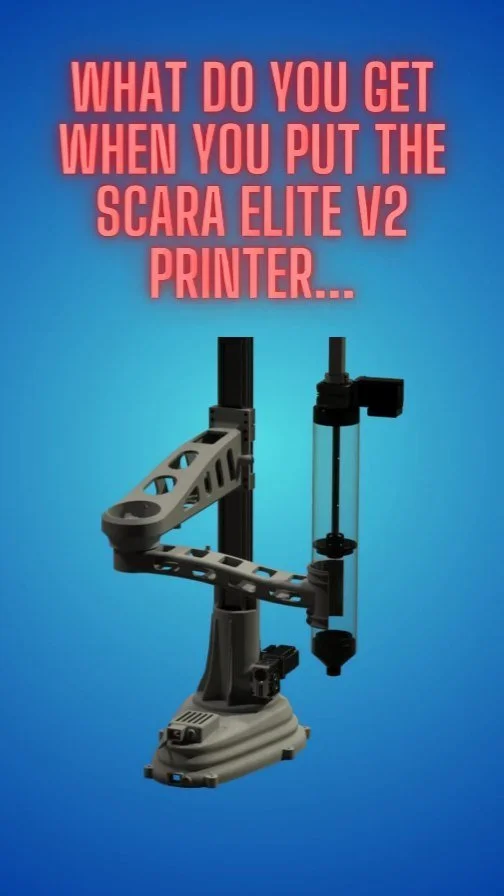

9. SMALL SIZE

The footprint of a 3D PotterBot is quite small because of our innovative traveling Z-axis design. This gives you the ability to create large objects without a huge printer. All that is required for our machine is a stable flat surface.

Our 3D PotterBot machines are able to print layers of varying thickness up to 0.63" (16mm), heights up to 4' (1219mm), the X axis up to 26" (660mm), and the Y axis up to 18" (457mm).

10. COMMON PRODUCT

Our machines are currently in use in hundreds of Architectural Institutes and Universities throughout the world. We also have many machines at the High School and Middle School levels printing continuously to the amazement of the students.